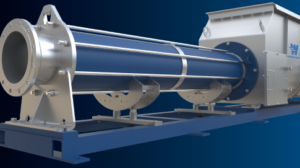

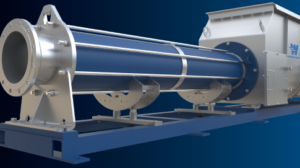

New powerful pump for large biogas plants

The BIO-MIX 200 conveys media to fermenters in biogas plants or in plants for anaerobic fermentation processes.

This media is then mixed in the pump with liquids, such as bovine manure or slurry.

In a comparative test operating at 150 cubic metres per hour, the pump achieves the highest flow rate in this pump class coupled with a higher pressure.

The robust and durable pump works within a large viscosity range, reliably pumping hydrophobic, abrasive and fibrous components, and boasting a long service life. This future-centric product is therefore a useful addition to the Pumpenfabrik Wangen pump range for the biogas sector.

The demand for regenerative energy is increasing worldwide and correspondingly so are the demands on energy generation - today, biogas plants, for instance in the USA and Brazil, are larger, have a bigger capacity, and are more seriously industrialised than even a few years ago.

In Europe too, high-performance pumps for biogas plants are increasingly sought after.

Wangen Pumpen has now responded to this demand and is expanding its existing BIO-MIX range with a powerful pump capable of delivery rates of up to 150 cubic metres per hour.

The BIO-MIX 200 pump is designed to reliably transport variable solids to the fermenters.

The manufacturer WANGEN Pumps has developed a process for this, in which the fermenters are variably fed with liquid feed.

Spigots on both sides of the pump enable liquid to be fed in for mashing, as required – with the entire hopper chamber being used as a mixing chamber. The hopper feed pump is generously sized and is easy to fill.

There is sufficient clearance along the entire length of the hopper for contaminants to be diverted and removed through the service openings. Moreover, the robust rotor comes in a range of different geometries.

Overall, the entire pump is designed to restrict wear and maintenance to a minimum.