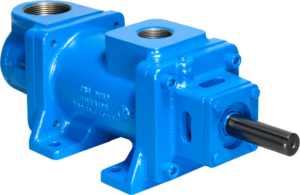

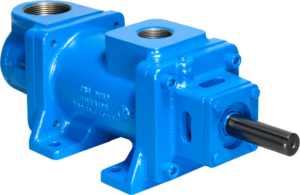

CIRCOR announces IMO 3-screw rotary pump technology

The IMO 3-screw design excels under low/vacuum inlet pressures and provides enhanced reliability and longevity.

The pumps are available in the 3D and 3E series for transfer/circulation of transformer insulating oil.

Series 3D pumps, available in 19 different displacements, incorporate full hydraulic balance that cancels axial and radial thrust loads due to discharge pressure.

The pump shaft is generously sized to allow belt drive if desired for mechanical seal versions.

The pumps are equipped with replaceable housings for simple repair, and most sizes are available with an optional steel case.

Series 3E pumps are designed and engineered for excellent suction capability over a wide range of fluid viscosities.

Offered in either cast iron or steel casing materials, the pump design features a uniform axial flow that results in a minimum of fluid pulsation and extremely quiet operation.

Flow rates (1 to 100 gallons per minute) are proportional to rotating speed when the pumps are operated within the recommended pressure range.

“It is a privilege to support our nation’s electric utilities infrastructure maintenance needs. These pumps are produced in Columbia, KY, USA. A high volume manufacturing plant, to facilitate superior quality and shipment,” said Don Parish, director marketing and business development.