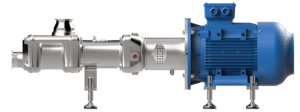

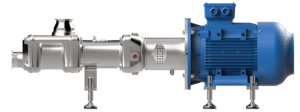

Wangen Pumps unveils improved Twin NG pump

The result is a proven hygienic pumping solution that performs better for longer, boosting uptime and reducing lifecycle costs for customers in the food sector.

Martin Stümpfle, product management Wangen Pumps, explained: “We are constantly seeking ways to improve pump performance and benefit our customers’ operations. The technical improvements we have made to our popular Twin NG pump deliver advantages ranging from contamination risk reduction to longer service life.”

Twin NG screw pumps are designed to reliably handle low to highly viscous, volatile, or gaseous products in applications that demand maximum hygiene and efficiency. Available in several sizes, the TWIN pumps offer a maximum flow rate of 200 m³/h and a maximum differential pressure of 25 bar.

The first design enhancement involves replacing the Twin NG’s motor coupling with a lantern coupling. This innovative feature prevents pump shaft misalignment, which reduces stress and vibration, thereby enhancing the lifespan of the pump and motor.

With less wear on pump shafts and bearings, maintenance requirements are minimised, and service intervals are extended. When maintenance is necessary, it is easier to perform since no shaft alignment is required. This lantern design thus lowers the total cost of ownership (TCO) and optimises uptime.