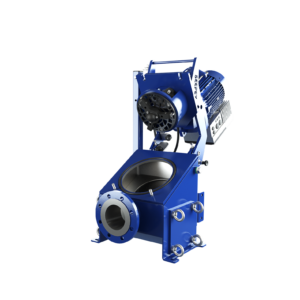

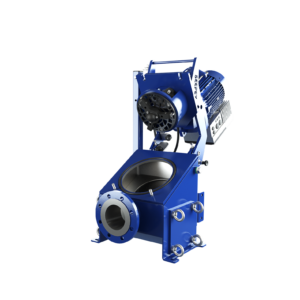

Seepex launches new easy maintenance macerator

Building on decades of macerator development expertise, the latest model is designed to protect pumps and downstream equipment by efficiently shredding solids and fibres while significantly reducing wear and unplanned downtime.

The upgraded macerator features optimised shear plate geometry to enhance flow performance, alongside replaceable, wear-resistant knives and a reversible shear plate that extends component life. Maintenance has been simplified through a quick-access design that allows servicing without lifting the unit, while an optional reverse operation enables operators to clear blockages without opening the housing.

The unit supports throughput rates of up to 100 m³/h and is available with motor ratings from 2.2 to 3 kW, making it suitable for a wide range of process requirements.

According to Seepex, the new Easy Maintenance Macerator delivers up to 80% faster cleaning, integrated debris separation and predictive maintenance functionality. These enhancements can double service life while significantly reducing spare parts consumption and overall operating costs.

“Our new macerator generation delivers significant improvements in handling, maintenance and cost efficiency,” said Guntram Schulz, global market and product manager at Seepex. “Customers benefit from reduced wear, longer service life and enhanced operational reliability.”

The Easy Maintenance Macerator is designed for use across municipal and industrial wastewater treatment, biogas plants, food and beverage production, fish processing, pulp and paper, and other applications where solids must be reliably shredded prior to pumping.

With its combination of performance, durability and simplified maintenance, Seepex’s latest macerator generation sets a new benchmark for operational reliability in solids handling systems.