Pushing boundaries

Founded by Tim and Donna Mast, the company set out to address the cryogenic industry’s toughest challenges in 2009.

CryoWorks’ journey from its foundation in Jurupa Valley, California, to becoming a global player in the cryogenic industry is a testament to its commitment to innovation, safety, quality and customer satisfaction.

Focused on meeting the growing demands for advanced cryogenic systems — ranging from rocket launches and cryogenic fuels to semiconductors and life sciences — CryoWorks has continually pushed technological boundaries, delivering mission-critical vacuum-jacketed pipe solutions.

In May 2024, Crane (NYSE: CR), a manufacturer of highly engineered industrial products, welcomed CryoWorks Inc. into its family of trusted brands.

This strategic move strengthened Crane’s portfolio in the energy transition and cryogenic solutions, enhancing its capabilities to meet evolving market needs. As CryoWorks joins forces with Crane, it is poised for even greater advancements, continuing to lead in providing cutting-edge cryogenic piping system solutions that meet and exceed customer expectations.

Mission-critical industries and applications

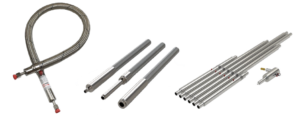

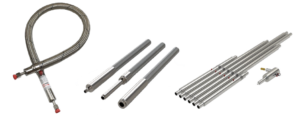

CryoWorks Inc. specialises in the design, engineering, and manufacturing of cryogenic vacuum insulated piping (VIP) systems, equipment and components. The company’s expertise spans various applications, including liquid nitrogen, liquid helium and liquid hydrogen systems.

With a team of highly skilled engineers and technicians, CryoWorks ensures that each product meets the highest standards of safety, efficiency and reliability. Recognising that each client has unique requirements, CryoWorks excels in creating custom cryogenic solutions from concept to reality.

This tailored approach has built trust and established a significant presence across various industries requiring cryogenic liquid gases:

Liquid Hydrogen (LH2)

With the continual demand for green energy fuels to reduce CO2 emissions, customers rely on CryoWorks combined decades of know-how for their LH2 (liquid hydrogen) application needs.

CryoWorks provides turnkey solutions tailored to the specific challenges of producing, transferring and storing LH2. Their engineering staff assists clients to reduce bottlenecks in their supply chain and accelerate the total project timeline. Their piping and components are used throughout the supply chain, including liquefaction, bulk storage, distribution and fuelling.

Liquified natural gas (LNG)

CryoWorks provides reliable piping systems and components in the transferring of LNG that is both safe and costeffective. CryoWorks LNG Vacuum Insulated Dual Containment piping and components are generally designed for the life of the facility and satisfy strict safety requirements of PHMSA and NFPA 59A. In house engineering services accelerate the engineering phase of any LNG project helping to reduce the total project life cycle and mitigate potential delays to 1st LNG. CryoWorks products can be found across the entire value chain including liquefaction, bulk storage, peak shaving and bunkering.

Industrial gas plants and air separation units (ASU)

For industrial gas plants and air separation units, CryoWorks provides Vacuum Insulated Piping (VIP) for the safe and efficient transfer of cryogenic fluids for the separation and storage of atmospheric air into produced liquified gases ready for distribution. With industry leading lead times, the company can be counted on to hit tight deadlines during plant turnarounds, planned maintenance, upgrades and facility expansions.

Rocket launch ground support

CryoWorks has provided vacuum insulated piping for some of the largest launch complexes in the USA. With its large diameter pipe manufacturing capabilities, broad technical expertise and experience in cleaning and code requirements for LOX, LH2 and LH4, and second-to-none internal engineering capabilities, CryoWorks is uniquely positioned to design and deliver safe and reliable ground support equipment throughout the lifecycle of any rocket programme.

Aerospace and defence

CryoWorks specialises in designing complex piping systems for cryogenic liquids used in aerospace and defense facilities. They serve major aerospace companies, providing field design, detailed layouts, drawings, fabrication and delivery of the Vacuum Insulated Piping (VIP) and field service and installation. CryoWorks experience and product lineup goes beyond just energy and aerospace. Every day, its Vacuum insulated piping and components are used across the continent, in just about every application needing cryogenic liquids and gases.

Environmental test chambers

CryoWorks provides vacuum insulated valve manifolds for OEM chamber manufacturers and end customer chamber upgrades. CryoWorks valve manifolds can be supplied with custom flow characteristics explicitly tailored for low-temperature environmental test chambers as well as Highly Accelerated Life Test (HALT) and Highly Accelerated Stress Screening (HASS) chambers.

Electronics and semiconductor production

For electronic and semiconductor production, CryoWorks serves customers that test semiconductor and electronic devices for applications in automotive, computers and flight hardware, supplying equipment connections for LN2 cold plates, SEM / MEMS, gas purifiers, testin- strip handlers and environmental temperature test chambers.

Molecular Beam Epitaxy (MBE)

MBE applications require an uninterrupted supply of high-quality LN2. CryoWorks supplies Vacuum Insulated Piping (VIP) and reliable phase separators to support this function. MBEs are used to manufacture semiconductor devices which require an ultra-high vacuum environment. To achieve this, the MBE’s cryopanel is cryogenically cooled using LN2 to capture impurities, making the LN2 supply equipment a vital part of the ultra-high vacuum process.

Life science freezing and storage

CryoWorks supports many applications for biotech, life sciences, research and pharmaceuticals. They offer turn-key systems including vacuum insulated piping (VIP), flex hoses, oxygen monitoring systems and alarms, emergency shut-off and one-fill/all-fill controls for cryo-freezers and cold rate freezers used in biological storage repositories of cord blood, human tissue, stem cell and bone marrow.

Helping universities and national labs understand the Universe

Cryogenics have a significant role in expanding our understanding of the world around us. CryoWorks supports universities and national labs, providing LN2 and LAr piping to cryostats, cryocoolers, superconducting magnets, refrigerators, MBE’s, Environmental Test Chambers and RF systems.

Beverage dosing and inerting

CryoWorks’ expertise in cryogenic piping systems is applied to the beverage and container industry. They provide equipment connections for cryogenic dosing for pressurisation of non-carbonated cans and bottling lines. For inerting applications, dosing is used to avoid oxidation in wine and edible oils (fats and foods with a high oil or fat content).

Food freezing and creamier ice cream

When people think of cryogenics in food, they often think of flash freezing. CryoWorks provides vacuum insulated piping systems, microbulk tanks, flex hoses, and oxygen monitors for food freezing, mixers, and chilling equipment. Liquid nitrogen is also popular among premium ice cream makers for creating a creamy texture, and CryoWorks is ready to meet this growing demand. Entertainment special effects

For entertainment and special effects, CryoWorks provides customized cryogenic piping systems that connect bulk and microbulk LN2 tanks to foggers, cannons, dry foggers, and burst effects. CryoWorks has supplied these systems for thrilling shows and roller coasters.

Cryotherapy

Cryogenic liquids have made their debut as a form of therapy, known as cold therapy. CryoWorks serves this growing industry, familiar with all major manufacturers and able to make connections to cryosaunas, cryo-chambers and other cryotherapy machines.

Innovations and technological advancements

The CryoWorks brand is committed to staying at the forefront of technological advancements in the cryogenic field. The company invests heavily in research and development to continuously improve its products and services. Recent innovations include higher pressure and thermally efficient bayonet connections, improved transfer lines and expanded engineering capabilities that enhance the safety and performance of cryogenic installations. Commitment to sustainability

As the world moves towards more sustainable practices, CryoWorks is committed to contributing to this global effort and focuses on developing energy-efficient cryogenic systems that reduce environmental impact. By optimising the performance of cryogenic equipment and minimising energy consumption, CryoWorks helps clients achieve their sustainability goals.

Customer-centric approach

At the core of CryoWorks’ success is its unwavering commitment to customer satisfaction and service. The company’s customer-centric approach ensures that each client receives personalized attention and support throughout their project. From the initial consultation to post-installation services, CryoWorks is dedicated to delivering exceptional value and committed to exceeding customer expectations. CryoWorks Inc. is poised for continued growth and innovation within the Crane umbrella. The company plans to expand its product offerings and explore new markets, leveraging its expertise to address emerging challenges in the cryogenic industry. With a strong foundation of technological excellence and a commitment to customer satisfaction, safety, and sustainability, the CryoWorks brand, a business of Crane Company, is well-positioned to lead the way in cryogenic solutions. As CryoWorks continues to push the boundaries of what is possible in cryogenic technology, it remains dedicated to delivering the highest level of service and value to its clients worldwide.

For more information. Visit: cryoworks.net