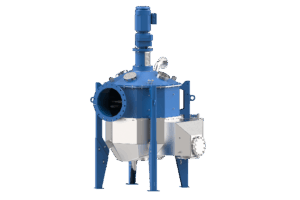

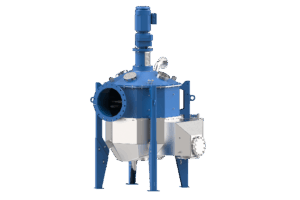

Optimise production with BIO-ROXX mixing module from Wangen Pumps

The BIO-ROXX module from Wangen Pumps accelerates the fermentation process and increases the biogas yield by mixing solid and liquid phases to prepare the ideal inoculum, limiting air introduction to a minimum and removing solid bodies such as stones.

Installed downstream of the dry substrate hopper and the liquid feeder and before the fermenter, the Wangen Pumps BIO-ROXX module delivers a homogeneous substrate that increases the decomposition rate in the Anaerobic Digestion plant and speeds up gas production.

Ideal for plant sizes of 1-10 MW, the BIO-ROXX module is a real asset in biomethane production, where high gas purity must be attained to meet the grid’s standards.

The BIO-ROXX features a sealed mixing chamber combined with a discharge pump below the fill line, so no air can enter and compromise the Anaerobic Digestion process.

The unique configuration of the mixing rods and blades inside the chamber ensures that organic solids are evenly suspended and diluted, enabling the anaerobic bacteria to thrive and convert the organic materials to biogas. The mixing process enhances the efficiency of the fermenter by reducing viscosity and preventing the formation of a 'float' layer, which occurs when larger, fibrous solids accumulate as a crust on top. By preventing floats and assuring low viscosity levels, the BIO-ROXX maintains optimal gas production, reduces the energy consumption of mixers, and prevents damage to the paddles used for stirring the fermenter contents.