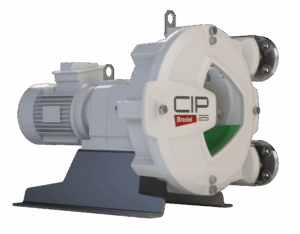

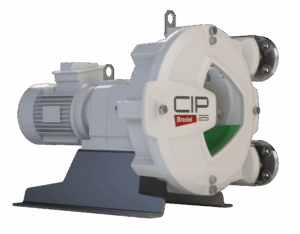

Learning more about the new Bredel CIP pump

The innovative Bredel CIP pump is engineered for hygienic, simplified and energy-efficient Clean-In-Place (CIP).

Alongside the new pump, WMFTS will showcase a comprehensive range of peristaltic and sinusoidal pumps, as well as hoses, which enable brewers and beverage producers to boost productivity while reducing energy consumption, water usage, and waste.

The Bredel CIP is designed with a new rotor to enable companies to achieve the required CIP velocities in various applications at beverage producers.

The Bredel CIP pump features automatic retractable compressing shoes that fully open the hose, allowing CIP fluid to flow at the optimal velocity for effective cleaning. By retracting the shoes during cleaning, hose compressions at high temperatures are eliminated, thereby extending hose life and reducing costs of replacement hoses.

For beverage and liquid food producers, Bredel CIP is ideal for transferring fruit puree, fruit concentrate, liquid sugar unloading, and flavour and colour dosing. Bredel hose pumps are widely used in beverage production due to their ability to reliably handle shear sensitive, abrasive or viscous products.

Steffen Knoedler, global business development manager - food & beverage at WMFTS, said: “The Bredel CIP sets a new benchmark in peristaltic hose pump technology for breweries and beverage producers. It ensures thorough CIP, eliminating the risk of spoiled product while delivering the required fluid velocity with extended hose life.

“Unlike standard hose pumps, the new pump avoids hose compression during CIP cycles by retracting the shoes while the pump remains stationary. This innovation significantly reduces wear during high-temperature cleaning, extending hose life and lowering replacement costs.

“The Bredel CIP also reduces energy consumption, as there’s no need to operate the pump during CIP. This combination of efficiency, reliability, and cost savings makes it a game-changer for hygienic fluid handling in beverage production.”