IMI agrees major anti-surge valve deal

The project will upgrade legacy IMI valves with new anti-surge valves to increase both system reliability and efficiency, while also driving improved environmental performance.

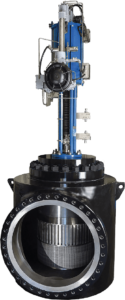

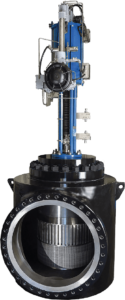

The replacement valves benefit from additive manufactured components complete with IMI’s patented DRAG™ technology. Its multi-stage, multi-path design directs fluid through a highly resistant tortuous path to incrementally reduce the inlet pressure. This limits the fluid velocity at the trim, eliminating the risk of vibration, noise, and erosion.

The IMI anti-surge valves also feature IMI’s SC/V actuators, which use a special piston design for smooth and precise operation, as well as IMI’s latest development, the high-capacity, high-precision digital pneumatic SHP (Smart High Performance) positioner.

The SHP positioner uses a control algorithm system and patented logic to deliver very low stroking times with high dynamic control. It also offers both online and offline diagnostic capabilities for monitoring the valve during operation and conducting step, valve signature and frequency tests.

With fugitive emissions posing a major sustainability challenge to offshore upstream production platforms, the new anti-surge valves include IMI’s EEEasy-Seal™ stem packing solution, which provides up to ISO Class AM FE leakage protection and is third-party certified to ISO 15848-1.

Giuseppe Buscemi, EMEA president of process automation at IMI, commented: “We are proud to once again assist our longstanding customer in North Sea with such a critical infrastructure upgrade. Valve design has come a long way in recent years and our ability to match state-of-the-art additive manufactured components with the very latest in positioning and stem packing technology was crucial to a successful re-tender.

“With environmental targets for offshore upstream production facilities becoming increasingly stringent, it is more important than ever that every component can make a tangible contribution to a site’s emissions reduction strategy. For this customer, our anti-surge valves will do just that.”

For more information on IMI’s range of anti-surge valves for upstream production facilities, visit: imi-critical.com/product/drag-compressor-recycle-anti-surge-valve/