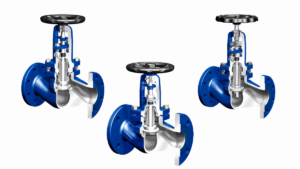

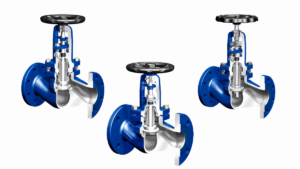

ARI USA highlights FABA® bellows sealed valves for leak-free isolation

Designed for exceptional reliability and long-term sealing performance, FABA® valves are ideally suited for applications requiring zero leakage and robust shut-off capabilities in steam, gas and liquid systems.

FABA® valves feature a proprietary “cut effect” design that ensures line contact sealing between the conical plug and seat ring, achieving a Class IV tight shut-off.

A fine-threaded stem increases seat pressure, while stellited or hardened sealing surfaces extend service life. Each valve is helium-tested and meets leakage rate “A” standards according to DIN EN 12266.

Engineered for durability, the FABA® Series incorporates a pressure-resistant, double-walled stainless steel bellows for added security in harsh industrial environments.

This reinforced bellows is welded to the stem to reduce vibration transmission, and is tested to withstand up to 10,000 load cycles. In FABA® Supra models, the bellows is further protected by a cover to mitigate water hammer effects.

The FABA® globe valve is designed for ease of maintenance and operational flexibility.

Ergonomic handwheels with a corrosion-resistant cataphoretic coating are included as standard, optional limit switches can be installed without loosening bonnet screws and select models have dual-function capabilities to operate as both stop and check valve.

Available in straight-through, angle, and Y-pattern configurations, the FABA® Series supports a wide range of standards, pressures, and sizes. Designs conform to DIN EN and ASME/ANSI specifications, with flanged, butt weld, socket weld, and threaded connection options.

Pressure classes range from PN 16 to PN 160 and ANSI 150 to ANSI 300, with sizes up to DN 400.