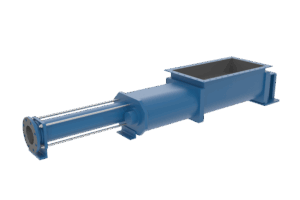

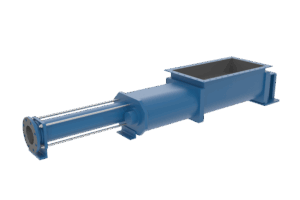

ALLWEILER AE-RG Hopper Pump Series delivers reliable performance for challenging solids handling

This Hopper Pump Series is designed for the efficient and reliable transfer of highly viscous, abrasive, or solids-laden materials, making it ideal for challenging applications such as wastewater treatment — especially dry sludge handling — biogas, and various other processing operations.

The AE-RG Hopper Pump Series features an optimised hopper design that enables smooth and efficient transfer of materials, including substances with up to 45% dry solids content.

This robust configuration ensures continuous pumping of non-free-flowing, dewatered, or fibrous products, ranging from highly viscous and sticky starch to heavily dewatered and solids-laden municipal sludge.

The series leverages progressing cavity pump technology to handle even the most challenging media, ensuring long-lasting, dependable operation in demanding settings.

Each pump includes two intermeshing augers, optimised for every application and available as either mixing or conveying screws; a combination of both is also possible.

This prevents bridge-building and clogging at the inlet hopper, guaranteeing uninterrupted performance with difficult-to-handle materials, without the need for separately driven, energy-consuming bridge-breakers.

The optional mixing screw design also allows customers to introduce conditioning agents or other additives through a bypass line into the inlet hopper, blending them directly into the main pumping media.