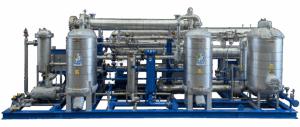

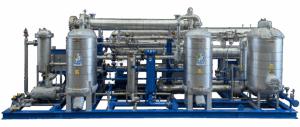

Advanced hydrogen purification in oil and gas applications

This fully customisable packaged skid offers an advanced approach to purifying hydrogen gas by removing both oxygen and moisture, helping oil and gas companies meet strict industry specifications.

The Deox-H2 + TSA system effectively handles inlet oxygen concentrations up to 4%, reducing oxygen levels to less than 1 ppmv.

In addition, it can process hydrogen gas with high moisture content, reducing water levels to below 1 ppmv.

The fully automatic system integrates essential subcomponents, instrumentation and controls into a single efficient package.

The inclusion of multiple regeneration strategies ensures zero gas emissions or losses, optimising operational efficiency and sustainability in oil and gas operations. Additionally, the multi-layered adsorbent bed provides a cost-effective solution, reducing operating expenses while ensuring the highest level of purification for oil and gas processes.

“With the Deox-H2 + TSA system, PSB Industries continues to push the boundaries of hydrogen purification technology,” said Brian Meyer, application sales manager, PSB Industries.

“Our goal is to provide businesses with solutions that not only meet the strictest purity standards but also offer long-term operational savings and environmental benefits."

PSB Industries manufactures and designs the Deox-H2 + TSA system in accordance with North American standards such as ASME, ANSI, NEC, UL, etc. and can further provide CRN registration for Canadian projects, ensuring it meets stringent industry standards for pressure vessels and safety. The system’s comprehensive design and customisable features make it a valuable asset for any hydrogen production facility.